When you walk into a truly exceptional home, it’s often the built-in details that leave a lasting impression. These elements—the elegant sweep of crown molding, the seamless integration of a custom library, or the precise lines of a coffered ceiling—are the work of architectural millwork.

Think of it as the custom-fit architecture within the architecture. It’s what bridges the gap between the structure of a building and the fine-art of its interior design, giving a space its soul and a distinct, polished character.

Defining the Art of Architectural Millwork

At its heart, architectural millwork refers to any custom wood component fabricated in a workshop and designed to be permanently installed in a building. Unlike a piece of furniture you might bring into a room, millwork becomes a part of the room itself. It’s built-in, immovable, and essential to the overall design story.

This craft is both an art and a science, covering a huge range of applications that are as functional as they are beautiful. It’s also a significant industry. Custom architectural woodwork and millwork specialists in North America alone reported sales of USD 8.9 billion in 2023. That figure is just a slice of a global market valued at over USD 100 billion, a testament to its critical role in high-end construction. For a deeper dive into the numbers, you can find more details in this market research report.

Distinguishing Millwork from Carpentry and Furniture

To really get a feel for what architectural millwork is, it’s helpful to understand what it isn’t. People often confuse it with finish carpentry or furniture making, and while they all involve masterful woodworking, their roles are very different.

- Finish Carpentry is primarily about on-site installation. A finish carpenter works with pre-made materials like standard trim, doors, and baseboards, cutting and fitting them on location. It’s more assembly than creation.

- Furniture includes all the freestanding pieces in a home—the dining table, the armchair, the dresser. These items are movable and not integrated into the building’s structure.

- Architectural Millwork is the beautiful middle ground. It involves the precision of furniture making, but its creations are custom-fabricated off-site and then permanently installed, becoming an integral part of the home’s architecture.

The key distinction lies in integration. Architectural millwork isn’t just placed in a room; it is designed to become part of the room itself, shaping its proportions, style, and flow.

The table below breaks down the key differences to help you see where each craft fits into a luxury design project.

Architectural Millwork vs Carpentry vs Furniture at a Glance

| Attribute | Architectural Millwork | Finish Carpentry | Furniture |

|---|---|---|---|

| Fabrication | Custom-made off-site in a workshop | Typically works with stock materials on-site | Custom or mass-produced, made off-site |

| Integration | Permanently installed and built-in | Assembled and installed on-site | Freestanding and movable |

| Design | Project-specific, designed for a unique space | Follows standard profiles and dimensions | Designed as a standalone object |

| Examples | Custom cabinetry, built-in libraries, paneling | Baseboards, door/window casings, crown molding | Tables, chairs, sofas, beds, dressers |

Understanding these distinctions is crucial. It ensures that when you’re planning a project, you’re speaking the right language and engaging the right artisans to bring your vision to life with the precision and permanence it deserves.

The Essential Elements of Architectural Millwork

While “architectural millwork” is a great umbrella term, its real magic lies in the individual components. These are the tools a designer or architect uses to layer in character, define a home’s style, and make a space truly functional. Think of them as the vocabulary of a well-designed interior—each piece tells part of the story.

Picture an empty room as a blank canvas. Architectural millwork provides the foundational brushstrokes, creating depth, shadow, and form long before any furniture arrives. It doesn’t just fill the space; it gives it a permanent, intentional shape.

Moldings and Trim: The Framing of a Room

Molding and trim are probably the most common forms of millwork, but their impact is often deceptively powerful. These are the linear pieces that outline a room’s architecture—where walls meet floors, walls meet ceilings, and around every door and window. They’re like the frame on a masterpiece, focusing the eye and completing the picture.

These essential components include:

- Crown Molding: This is the elegant transition between the wall and ceiling. The right crown molding can make a room feel taller and more grand, and its scale can completely change the perceived proportions of the space.

- Baseboards: These are the unsung heroes that protect the bottom of the wall while creating a crisp, clean line where it meets the flooring.

- Casings: This is the trim that frames your doors and windows, adding substance and detail to these crucial openings.

Without these finishing touches, a room can feel boxy and incomplete. But by adding them, you introduce subtle layers that catch light and create shadows, contributing to a much richer visual experience. For those wanting to turn a traditional feature into a true showstopper, you can explore various creative crown moulding designs that really make a statement.

Custom Cabinetry: Where Function Becomes Form

This is where architectural millwork truly shines, blending flawless utility with undeniable beauty. Unlike stock cabinets pulled from a shelf, custom cabinetry is designed and built for one specific purpose in one specific space. This approach ensures every single inch is put to work, both for function and for a seamless look.

The category is incredibly broad, covering everything from a professional-grade chef’s kitchen to a perfectly organized walk-in closet or a sophisticated home bar. The real power of custom work is its ability to perfectly align with a homeowner’s lifestyle and the home’s unique architectural voice. It’s the functional heart of a home, crafted with the precision of fine furniture.

Wall Paneling: Adding Texture and History

Wall paneling is a classic millwork technique that brings texture, depth, and even a sense of history to an interior. From the traditional elegance of raised panels in a formal dining room to the clean, modern lines of shiplap in a coastal retreat, paneling can completely transform a room’s atmosphere.

A few popular styles you’ll see are:

- Wainscoting: Paneling that covers the lower portion of a wall, often topped with a decorative chair rail.

- Board and Batten: A style that uses wide boards and narrower strips (the battens) to create a geometric pattern that feels both rustic and transitional.

- Shiplap: Horizontally installed planks that create a clean, linear look that’s become a favorite in contemporary and modern farmhouse designs.

Paneling does more than just decorate a wall; it adds a solid architectural layer that gives a room a sense of permanence. It’s a powerful way to establish a specific design language, whether you’re aiming for historical grandeur or minimalist calm.

Architectural millwork elements are not isolated decorations. They work together as a system to create a cohesive interior language, ensuring every built-in component speaks to the others in the same design dialect.

Built-Ins: Creating Purposeful Spaces

Finally, we have built-ins—the most bespoke category of architectural millwork. These are custom-designed features integrated directly into a room’s structure to serve a very specific function. They turn awkward, unused nooks into valuable real estate and create focal points that define what a room is for.

Some of the most common built-ins we design and build include:

- Bookshelves and Libraries: Floor-to-ceiling shelving can transform an entire room into a dedicated space for reading, study, and display.

- Window Seats: This classic feature adds charming, integrated seating and often provides a clever bit of hidden storage.

- Entertainment Centers: Custom units designed to seamlessly house media equipment, hiding wires and clutter for a polished, clean look.

- Mudroom Cubbies and Benches: These are highly functional solutions for organizing busy entryways with dedicated spots for coats, shoes, and bags.

These elements are the ultimate expression of custom design. They solve everyday problems while adding immense character, making a home feel truly tailored to the people who live there. Once you understand these core components, you begin to see how architectural millwork moves beyond simple construction and becomes a true form of interior artistry.

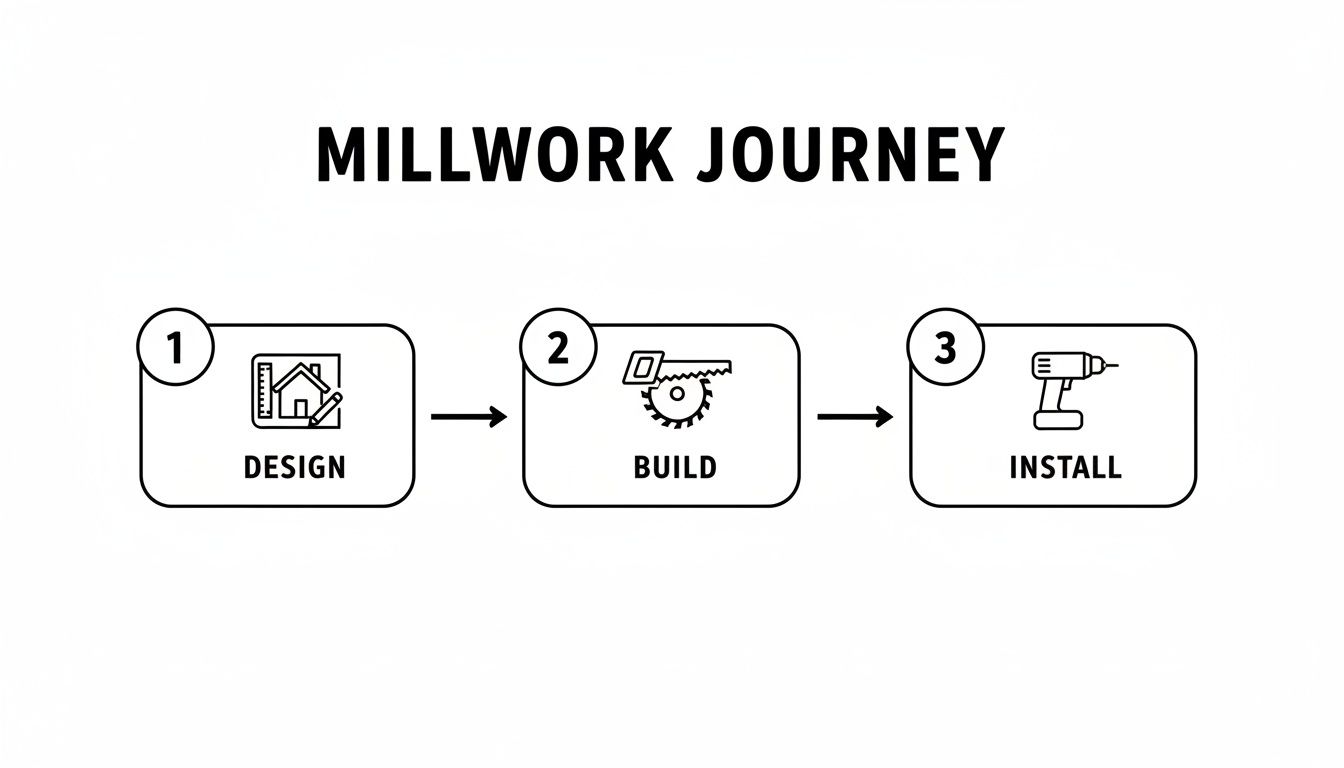

From Sketch to Structure: The Millwork Journey

Every stunning piece of architectural millwork starts not on a workshop floor, but as an idea. The journey from a designer’s concept to a flawless, installed feature is a finely tuned dance between creative vision and technical precision. For homeowners, architects, and designers, understanding this workflow is the key to ensuring the final result is a perfect reflection of what was originally imagined.

Think of it as a relay race where each leg is just as important as the last. Every phase builds on the one before it, with crucial checkpoints along the way to guarantee that what’s drawn on paper is exactly what gets built, finished, and fitted into the home.

The infographic below neatly sums up this three-act play.

It gives you a bird’s-eye view of how a design moves from blueprints to a specialized workshop, and finally, to a seamless installation on-site.

Phase 1: Design and Specification

It all begins with the architectural plans. The designer or architect lays out the vision—defining the location, scale, and style of the millwork. These drawings are the starting point, setting the aesthetic and functional goals for everything from built-in cabinetry to elaborate wall paneling.

From there, the millwork company’s specialists step in. Their drafters translate the design into meticulously detailed shop drawings. These aren’t just sketches; they are the project’s technical bible, specifying every single dimension, joint, material, and finish with absolute clarity.

This is arguably the most critical checkpoint in the entire process. Before a single piece of wood is cut, all stakeholders—the client, designer, and architect—must review and approve these shop drawings. This sign-off ensures everyone is on the same page, preventing costly errors down the line and guaranteeing a perfect fit. To see how this fits into the grand scheme of things, it’s helpful to understand the complete architectural design process steps.

Phase 2: Fabrication in the Workshop

With approved drawings in hand, the project moves from paper to the workshop floor. This is where raw materials are transformed into refined architectural elements through a sophisticated blend of modern technology and old-world craftsmanship.

The fabrication process typically unfolds in these key steps:

- Material Selection and Prep: The specified wood or other material is hand-picked for its quality, grain, and color. It’s then left to acclimate to the workshop environment, a crucial step for ensuring stability.

- Cutting and Machining: Using the digital shop drawings as a guide, advanced machinery like Computer Numerical Control (CNC) routers make incredibly precise and consistent cuts. This technology ensures every component is flawlessly executed.

- Assembly and Craftsmanship: This is where the artistry comes in. Highly skilled artisans take the machined parts and bring them together, fitting joints, carving details, and ensuring every element aligns perfectly.

- Finishing: The assembled piece is moved to a dedicated, dust-free finishing booth. Here, it’s sanded, stained, painted, or lacquered to achieve a flawless, durable surface that simply can’t be replicated on a busy construction site.

One of the greatest advantages of true architectural millwork is that all the messy, complex work happens in a controlled workshop, not in your home. This drastically reduces on-site disruption, dust, and fumes, making the final installation cleaner, faster, and far more efficient.

Phase 3: Installation and Completion

Once fabrication and finishing are complete, each component is carefully wrapped and transported to the project site. The final act is the installation, where a team of specialists meticulously fits the custom-made elements into the home’s architecture.

This step demands incredible precision. Installers work from the same shop drawings, scribing edges to meet imperfect walls and making micro-adjustments to achieve that perfect, built-in look. After every piece is in place, they perform final touch-ups, leaving behind a finished product that looks as if it has always been a part of the home. It’s the moment the entire journey comes together, bringing the original vision to life.

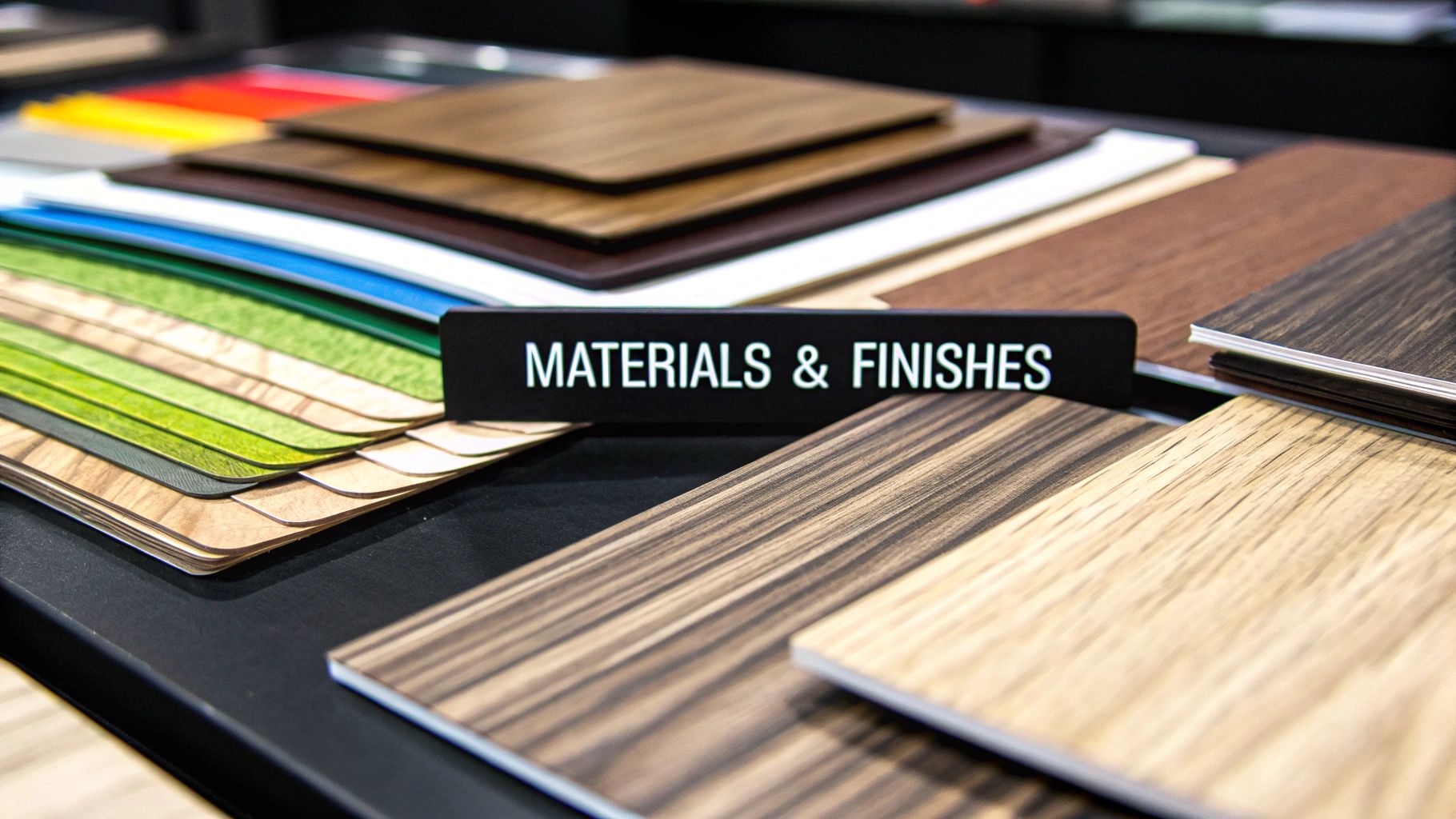

Choosing Materials and Finishes for Lasting Elegance

If the design is the mind of architectural millwork, then the materials and finishes are its heart and soul. The choices you make here define the entire sensory experience of a space—not just how it looks, but how it feels, and how it holds up over the years. It’s a careful balance between aesthetics, real-world durability, and the unique story you’re trying to tell with the architecture.

This process is about so much more than picking a color. It’s about understanding how a material will age, how it plays with light, and how it feels under your fingertips. This is the difference between a project that looks great on day one and one that gathers character and becomes even more beautiful with time.

The Foundation: Your Choice of Materials

The material is the very substance of your millwork. It’s the source of its strength, texture, and character. In high-end design, the palette extends far beyond standard lumber, with each option bringing something unique to the table.

Solid woods have always been the gold standard, and for good reason. Species like walnut, white oak, and mahogany are treasured for their rich grain patterns, satisfying weight, and timeless appeal. They are the perfect choice for high-touch elements like handrails, custom cabinet doors, or bar tops that are meant to be seen and used.

But engineered materials play a huge and vital role in modern millwork. Premium Medium Density Fiberboard (MDF), for instance, offers incredible stability, making it the go-to substrate for large painted panels that absolutely must not warp. Likewise, specialty plywoods provide the strength and screw-holding power needed for robust cabinet boxes and other structural pieces.

- Wood Veneers: These thin slices of real wood, applied to a stable core like MDF, open up a world of possibilities. Veneers allow designers to work with stunning and rare woods—think rift-sawn oak or bookmatched walnut—in a way that’s both sustainable and dimensionally stable.

- Alternative Materials: The best millwork often incorporates other materials for contrast and function. This could mean metal inlays for a crisp, modern detail, glass panels for beautifully lit display cabinets, or stone tops for integrated vanities.

Truly exceptional work often involves a strategic mix. A master craftsman might use solid wood for the frames, veneered panels for the doors, and a high-grade plywood for the cabinet box. This approach leverages the best qualities of each material to create a final product that’s superior in every way.

The Finishing Touch: Perfecting the Surface

A finish isn’t just a layer of color; it’s a protective shield against moisture, wear, and UV light that also happens to define the final look. Applying a world-class finish is a genuine art form, done in a controlled, dust-free environment to achieve a flawless surface you simply can’t replicate on a job site.

The finish is the bridge between the raw material and the final aesthetic. A world-class finish should feel as good as it looks, creating a smooth, durable surface that enhances the natural beauty of the material beneath it.

For transparent finishes, stains add color while letting the natural wood grain shine through. This is followed by several layers of a clear protective topcoat, which can be specified in various sheens—from a soft matte that feels raw and organic to a deep, high-gloss polish for a more formal, reflective look.

Painted finishes, usually applied over MDF for its perfectly smooth surface, offer an infinite spectrum of color. The process is meticulous, involving multiple coats of primer and paint with sanding between each layer to build up an impeccable, durable surface.

For a truly custom look, designers often turn to specialty finishes:

- Cerusing: A beautiful technique where the wood’s grain (typically oak) is filled with a contrasting pigment to highlight its natural texture.

- High-Gloss Polishing: A painstaking, multi-step process that builds up layers of lacquer to achieve a mirror-like sheen.

- Distressing: A suite of artistic techniques used to give new millwork the authentic, time-worn appearance of a cherished antique.

To help visualize how these materials fit into a project, this table breaks down the most common choices in luxury millwork.

Comparing Common Materials in High-End Millwork

| Material | Best For | Aesthetic & Feel | Durability & Maintenance |

|---|---|---|---|

| Solid Wood | High-touch surfaces, cabinet frames, molding, furniture-quality pieces. | Timeless, warm, and authentic. Rich grain patterns. | Very durable but can expand/contract with humidity. Requires proper sealing. |

| Wood Veneer | Large surfaces like doors, wall panels, and casework. | Offers exotic and consistent grain patterns sustainably. | Excellent stability when bonded to a quality substrate like MDF. |

| MDF (Medium Density Fiberboard) | Painted surfaces, non-structural panels, and complex shapes. | Perfectly smooth and uniform, ideal for flawless paint application. | Very stable, but susceptible to water damage if not sealed perfectly. |

| Plywood (High-Grade) | Cabinet boxes, drawers, and structural shelving. | Strong and practical; the interior beauty is in its function. | Excellent strength and screw-holding power. Very durable. |

| Metals, Glass, Stone | Inlays, accents, backsplashes, countertops, display doors. | Adds modern contrast, texture, and a touch of luxury. | Varies by material; generally very durable and chosen for specific functions. |

Ultimately, understanding the interplay between a material and its finish is what separates good millwork from great millwork. This knowledge gives you the power to make confident decisions, ensuring the final installation not only realizes your design vision but also stands as a lasting testament to true craftsmanship.

How to Budget for Custom Architectural Millwork

Understanding the value of architectural millwork is one thing, but planning for its cost is another entirely. Budgeting for custom work isn’t about hunting for the cheapest quote; it’s about making a smart, lasting investment in your home. Because every project is truly bespoke, there’s no off-the-shelf price list. But if you understand what drives the cost, you can plan with confidence.

Ultimately, the final number on any millwork project is a blend of four main ingredients: design complexity, material quality, finish level, and the labor required to bring it all to life. It makes sense, right? A simple, painted bookshelf will naturally cost less than an entire library paneled in quarter-sawn oak with hand-carved details and a flawless, high-gloss finish. Every decision you make is part of the final equation.

The demand for this level of craftsmanship is strong. In 2023, the American custom millwork industry generated USD 8.9 billion in sales, growing almost three times faster than the general millwork market. This points to a healthy appetite for high-quality, custom solutions and a deep well of artisans ready to take on ambitious projects. You can find more details on the growth of the architectural woodwork industry on ibisworld.com.

Key Factors That Influence Millwork Costs

To set a realistic budget, you have to know where the money is actually going. It helps to think of it less as one single price and more as a collection of individual choices, each with its own financial weight.

Here are the main elements that will shape your project’s bottom line:

- Design Complexity: The more intricate the design, the higher the cost. Gentle curves, detailed carvings, delicate inlays, and complex joinery all demand a higher level of skill and far more time, both on the drafting table and on the shop floor.

- Material Selection: This one’s straightforward. Solid walnut is going to be more expensive than paint-grade MDF. Your material choices, from the species of wood to the quality of the drawer slides and hinges, are a major line item.

- Finish Level: A perfect, multi-coat lacquer finish is a painstaking, labor-intensive process that can only be done right in a controlled environment by a skilled finisher. This is a world away from a simple, single coat of paint.

- Scope and Scale: The sheer volume of work is a direct factor. Budgeting for a full-room, floor-to-ceiling library is a completely different exercise than planning for a single built-in window seat or a run of crown molding.

It’s a common mistake to fixate on material costs alone. In high-end millwork, skilled labor often accounts for over 50% of the total project price. The expertise poured into the design, fabrication, finishing, and installation is the most valuable component you’re investing in.

Smart Budgeting and Value Engineering

Having a budget doesn’t mean your hands are tied. Value engineering is a practical process of refining a design to hit a specific number without compromising its soul or aesthetic intent. It’s all about making smart trade-offs.

For example, you could specify solid wood for high-touch surfaces like cabinet doors and drawer fronts but choose a more economical, high-quality plywood for the cabinet boxes, which are mostly hidden from view. Or maybe you simplify the detailing in a secondary space, like a guest closet, to free up more of your budget for a show-stopping statement piece in the living room.

Knowing these levers allows you to have a productive conversation with your designer and millwork partner. This kind of detailed cost analysis is a crucial part of understanding luxury home construction costs in general. When planned thoughtfully, your investment in architectural millwork won’t just achieve your vision—it will deliver enduring quality and value for decades.

Sustainability and Modern Trends in Millwork Design

Architectural millwork has never been a static craft. It’s a living art form, constantly mirroring the bigger shifts in design, culture, and our growing environmental awareness. The most admired projects today are defined just as much by their responsible material choices as they are by their stunning aesthetics.

This evolution is pushing us—designers, architects, and artisans—to create spaces that aren’t just beautiful, but are also relevant and built with the future in mind.

A Focus on Responsible Materials

Sustainability isn’t just a buzzword in high-end design; it’s a core expectation, and millwork is right at the center of the conversation. Clients today want to know the story behind the materials. Where did this wood come from? Is it healthy for my home?

This has put a huge emphasis on specifying Forest Stewardship Council (FSC) certified woods, which is our guarantee that the timber comes from responsibly managed forests. The conversation also extends to the air we breathe inside our homes. Low-VOC (Volatile Organic Compound) finishes are now the gold standard, ensuring a flawless and durable surface without compromising indoor air quality.

The Influence of Modern Design Movements

The look and feel of custom millwork are also being shaped by powerful global design trends. The craft is no longer limited to ornate, traditional profiles. Instead, it’s a crucial element in creating clean, contemporary, and nature-focused interiors.

Two movements in particular are making a big impact on millwork design:

- Biophilic Design: This is all about connecting us with nature inside our built environments. For millwork, that means letting the natural beauty of the wood shine through—using organic forms, celebrating authentic grain patterns, and choosing finishes that highlight the material’s texture. Imagine rift-sawn white oak paneling that wraps a room in warmth and subtle pattern.

- Refined Minimalism: This isn’t about creating a cold, stark space. It’s about using custom millwork to design seamless, uncluttered interiors that feel calm and orderly. Think handleless cabinetry with discreet integrated pulls, clever concealed storage, and expansive, clean-lined panels that create a powerful sense of serenity.

Today’s luxury is defined by intentionality. Custom millwork achieves this by integrating purpose, sustainability, and aesthetic clarity into the very fabric of a home’s architecture.

This dual focus on beauty and responsibility is fueling major growth in the industry. The global millwork market is on track to hit USD 146.08 billion by 2032, driven largely by high-end residential and commercial projects that demand custom details and eco-conscious materials.

As standards tighten, the best millwork partners are those who deliver on all three fronts: aesthetics, performance, and sustainability. You can discover more insights about millwork trends on metastatinsight.com to see where the market is headed. By embracing these modern currents, architectural millwork continues to create spaces that are not just beautifully crafted, but intelligently and responsibly designed.

Answering Your Millwork Questions

Let’s wrap up with a few questions that almost always come up when planning a high-end project. Getting these details straight from the start will give you the confidence to talk shop and make informed decisions with your design team.

What’s the Real Difference Between Custom and Semi-Custom?

This really boils down to freedom versus formula.

Custom architectural millwork is the truest form of bespoke design. It’s conceived and built entirely from a blank slate, specifically for your space. Every dimension, material, and finish is a choice, not a compromise. Think of a library where the bookcases are designed to the inch to fit the room’s unique architecture and your personal collection—that’s custom work.

Semi-custom, on the other hand, starts with a kit of parts. It uses standard-sized components and pre-set designs as a foundation. You can still make some choices on finishes, hardware, and minor dimensional tweaks, but you’re working within a pre-defined system. It’s a practical solution for certain areas but can’t offer the complete creative control that makes a space truly one-of-a-kind.

How Long Does a Custom Millwork Project Actually Take?

The honest answer? It depends entirely on the scale and complexity of the work. For something relatively contained, like fabricating and finishing crown molding for a few rooms, you might be looking at several weeks from the day you sign off on the design.

But for a more immersive project—say, a full custom kitchen, a paneled study, or a wine cellar with intricate built-ins—the timeline stretches out considerably. It’s not uncommon for these to take anywhere from 3 to 6 months, and sometimes even longer. That timeline accounts for everything: initial design, hyper-detailed shop drawings, client approvals, the actual fabrication, a multi-step finishing process, and the final, careful installation on-site. Each step is crucial and can’t be rushed.

A great millwork partner will give you a detailed and realistic schedule right at the beginning. This isn’t just a loose estimate; it’s a critical project management tool that keeps everyone on the same page and ensures the millwork integrates perfectly with the rest of the construction.

How Do I Find the Right Millwork Company?

Choosing your artisan is one of the most critical decisions you’ll make. Start by digging into their portfolio. Does their work reflect the quality, style, and scale you envision for your own project? Look for consistency and an eye for detail. And don’t be shy—ask for references from past clients, but also from the architects and designers they’ve worked with.

The best firms operate with total transparency. They’ll have a clear process, provide shop drawings so detailed there are no surprises, and maintain open communication from start to finish. Pay close attention to their finishing capabilities. Ask them to walk you through their process and show you examples. A flawless finish is what separates good millwork from spectacular millwork.

Is Architectural Millwork Really a Good Investment?

Without a doubt. Beautifully designed and expertly crafted architectural millwork is a defining feature of a luxury home. It does more than just look good; it adds character, enhances functionality, and creates a sense of permanence and quality that you can feel.

It’s the element that elevates a structure from a well-built house to a truly bespoke home. From a practical standpoint, this level of detail and customization can significantly increase a property’s market value, setting it apart in a crowded market. It’s an investment in timeless design that pays dividends for years.

Finding the right professionals is the first step toward creating an extraordinary space. At Haute Design, we connect discerning clients with the nation’s leading architects, interior designers, and builders who specialize in luxury residential projects. Explore our network of vetted professionals and find the perfect partner for your vision.